Type of Glass Fiber yarn

Glass Fiber Yarn

Glass Fiber is a material made by 5 - 13microns diameter non-organic fiber which is made

by melting the mixed refined glass raw materials at high temperature at 1200-1500℃.

Glass Fiber yarn is used with two tyes of single yarn and plied yarn according to its usage.

| Yarn Description |

Filament Dia.(㎛) |

Tex(g/1000m) |

Tensile Strength(Kgf) |

| ECD 900 1/0 1.0 Z |

5 |

5.5 |

>0.30 |

| ECD 450 1/0 1.0 Z |

5 |

11.0 |

>0.56 |

| ECE 225 1/0 0.9 Z |

7 |

22.0 |

>0.90 |

| ECG 150 1/0 0.7 Z |

9 |

33.5 |

>1.20 |

| ECG 150 1/2 3.8 S |

9 |

67.5 |

>2.10 |

| ECG 150 1/3 3.8 S |

9 |

100.0 |

>3.20 |

| ECG 75 1/0 0.7 Z |

9 |

67.5 |

>2.40 |

| ECG 75 1/2 3.8 S |

9 |

135.0 |

>4.20 |

| ECG 75 1/3 3.8 S |

9 |

202.0 |

>6.50 |

| ECG 37 1/0 0.7 Z |

9 |

135.0 |

>3.00 |

| ECG 37 1/3 3.8 S |

9 |

405.0 |

>8.50 |

Glass Fiber Texurized Yarn & Glass Roving

Glass Fiber texturized yarn is made by glass fiber yarn with texturized machine. And, it is

used in manufacturing insulation fabric and filter bag by using its heat insulation and

filtering property. Glass roving is used for strength reinforcement of FRP such as vessel

and septic tank.

Customary Glass System

Count Per Inch |

Filament Dia.(㎛) |

Tex(g/1000m) |

Denier

(g/9000) |

| Texturized Yarn |

ECDE 75 1/2 (T) |

6 |

148 |

1,332 |

| ECDE 75 1/3 (T) |

6 |

222 |

1,998 |

| Roving |

300 |

13 |

300 |

2,700 |

| 1,200 |

17 |

1,200 |

10,800 |

| 2,400 |

24 |

2,400 |

21,600 |

| 4,400 |

24 |

4,400 |

39,600 |

Sewing Thread

Sewing Thread is used for sewing which require high temperature and chemical resistance.

Main application: sewing for filterbag, insulation cover

| Style |

Yarn count

(Tex) |

Color |

Thickness

(mm) |

Continuous Use

(℃) |

PTFE coated glass fiber Sewing Thread

|

180 |

Dark Brown |

0.30 |

300 |

PTFE Fiber Sewing Thread

|

140 |

White |

0.30 |

250 |

| Basalt Fiber Sewing Thread |

160 |

Dark Green |

0.30 |

350 |

| Steel Fiber Sewing Thread |

200 |

Gray |

0.25 |

1,100 |

Property of Glass Fiber Fabrics

KGF glass fiber fabrics are mostly fabricated by "E"glass yarn and glass fiber fabric is designed and supplied to the customers according to the requirement of the customers.

Type of construction

Mechanical Property

| High tensile strength |

Glass fiber is one of the fibers that have the highest tensile strength. Its weight is lighter than that of steel wire but its tensile strength is stronger than that of steel wire |

| Good dimensional stability |

Glass fabrics has low elongation percentage(below 3%) and so has excellent dimensional stability |

| High heat resistance |

Glass fiber fabric is applied in high temperature working conditions with relatively cheaper investment. Glass fabric can stand about 50% tensile strength at 700℉(371℃) and about 25% at 482 ℃. Softening point is 846℃ and melting point is 1121℃ |

| Incombustibility |

Glass fiber fabric made of inorganic materials are noninflammable fabric and applied to especially in the dangerous places of fire. |

| High thermal condutivity |

Glass fiber fabric emit heat more rapidly and suitable for insulation |

| chemical resistance |

Like glass itself, glass fiber fabric is highly resistant to attrack by most chemicals |

| Electric insulation |

Excellent heat resistance property and low hygroscopic. And, has a superior electric insulation which is applied to the fields of electric industry |

| Endurance |

Safe from sunlight, dust fungi & bacteria |

| Economic |

Economical material comparing with other similar fabrics |

Chemical composition & Major mechanical property

|

SiO₂ |

Al₂O₃ |

B₂O₃ |

MgO, CaO |

R₂O |

ZrO₂ |

Character |

| E-glass |

52~56 |

12~16 |

5~10 |

20~25 |

0~0.8 |

|

Electric insulation |

| C-glass |

60~67 |

2~6 |

0~8 |

10~20 |

8~15 |

|

Acid resistant |

| S-glass |

63~64 |

23~25 |

0.01max |

10max |

0~3 |

|

High tensile strength |

| AR-glass |

55~65 |

0~5 |

0~4 |

0~12 |

13~18 |

12~21 |

Alkali resistant |

Major mechanical property(E-glass)

| Specfic Gravity |

2.54 |

| Tensile Strength |

150kg/㎟ |

| Elongation(Max) |

4% |

| Moisture Absorbency(Max) |

0.30% |

| Softening Point |

846℃ |

| Thermal Conductivity |

0.86㎉/m hr ℃ |

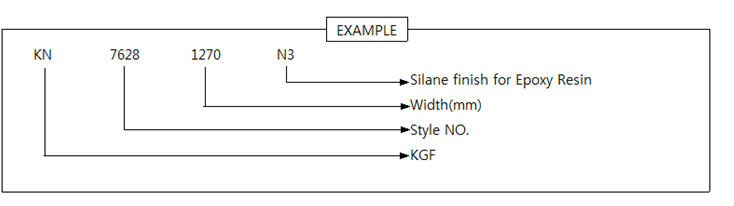

KGF reference code data of glass fiber fabrics

KGF Glass Fiber Fabric is manufactured in various kinds of thickness, weight and width by fabrication method.

And also, these are classified by final treament method such as heat treatment, surface treatment, prepreg and

coatings

Heat treatment and Silane finish

| Code |

Condition of Treatment |

Remark |

| -HS |

Loom-state |

|

| -S |

Heat Treatment |

|

| -N1 |

Silane finish for phenolic or epoxy resin |

|

| -N2 |

Silane finish for unsaturated polyester resin |

|

| -N3 |

Silane finish for epoxy resin |

|

Prepreg and coating

| Code |

Condition of Treatment |

Remark |

| -PHC |

Phenolic resin prepreg |

|

| -POC |

Polyester resin prepreg |

|

| -EPC |

Epoxy resin prepreg |

|

| -AC |

Acrylic binder coating |

|

| -PVC |

PVC resin coating |

|

| -MC |

Melamine resin coating |

|

| -PU |

Polyurethane resin coating |

|

| -SR |

Silicone rubber coating |

|

| -SV |

Aluminum powder coating |

|

| -AL |

Aluminum foil laminating |

|

※ Please contact us for special application. Special specifications are available at request.

Heat treatment & Coatings

Glass fiber fabric is possible to use without treatment and also widely used according to those specific usage with suitable treatments or coatings such as heat treatment, silane finish, prepreg, coating and laminating.

Heat Treatment

In order to enhance the compatibility on twisting / weaving, binders such as oil, agent is used when fiber forming and beam sizing.. Heat treatment process remove various binders according to the application.

Silane Finish

It is surface treatment on fabrics with coupling agents compatitable with several resins.

Prepreg

To make a cloth, undergoes heat cleaning and coupling agent process, into a semi-cured condition by soaking it in the mixture with an appropriate hardner. resins such as epoxy resin, phenol resin, unsaturated polyester and others by a certain ratio

Coating

It is surface treatment with acrylic resin, silicone resin, urethane resin or other special resin according to the application

Laminating

It is binding process with glass fiber fabric and aluminium foil sheet, film or paper.